in the present hyper-competitive international market place, makers are consistently looking for methods to enhance performance, decrease fees, and keep the highest amounts of good quality. standard methods of top quality Command are frequently time-consuming and susceptible to human error. This is when vision measurement device suppliers are stepping in with modern alternatives that are revolutionizing producing processes. This information will delve into how advanced eyesight measurement technology, specifically concentrating on Easson's chopping-edge three-axis CMM equipment, is not just Assembly present demands, but actively long term-proofing your complete production field.

Table of contents:

AI Integration and Automation: The Next Frontier in Measurement

authentic-Time details Analysis: Minimizing Downtime, Maximizing Output

Easson’s three-Axis CMM: primary the demand in Scalability and Adaptability

AI Integration and Automation: the subsequent Frontier in Measurement

The integration of synthetic Intelligence (AI) and automation is now not a futuristic idea; it’s a present-day reality radically maximizing the abilities from the vision measurement machine. AI algorithms empower these devices to find out from wide datasets, autonomously optimize measurement parameters, and identify even essentially the most refined defects with unparalleled speed and accuracy. This interprets to a significant reduction in human intervention, reducing the chance of errors and accelerating inspection periods. automatic managing units more streamline operations by seamlessly incorporating measurement processes into the prevailing manufacturing line, resulting in a hugely effective and optimized workflow. The greater throughput allows brands to fulfill demanding output schedules devoid of compromising high quality.

true-Time details Investigation: Minimizing Downtime, Maximizing Output

serious-time information Assessment is proving to become a pivotal Resource for makers striving to reduce pricey manufacturing downtime. Modern vision measurement methods are actually equipped with robust software platforms effective at providing instant and actionable feed-back on significant dimensions, tolerances, and course of action variations. This instantaneous knowledge stream enables proactive identification of opportunity troubles, like premature Software wear, machine calibration deviations, or substance inconsistencies, very long just before they escalate into substantial defects or catastrophic creation stoppages. By leveraging this serious-time intelligence, suppliers can employ instant corrective steps, enhance system parameters, and in the end be certain constant, uninterrupted creation when minimizing wasted methods and scrap materials.

Easson’s 3-Axis CMM: main the Charge in Scalability and Adaptability

Easson's three-axis CMM (Coordinate Measuring Machine) equipment are within the vanguard of vision measurement technology, providing unparalleled scalability and adaptability to fulfill the evolving requires of contemporary manufacturing. These equipment are meticulously engineered to support a various number of component dimensions, advanced geometries, and different substance sorts, producing them ideally suited to a wide spectrum of producing programs, from aerospace to automotive. As in depth on https://zh-easson.com/products/visual-video-cmm-measurement-machine-with-3-axis-001%CE%BCm-linear-encoder, Easson's equipment are renowned for his or her Remarkable accuracy, boasting impressive 0.001μm linear encoders, guaranteeing the highest probable level of precision and repeatability. Their modular structure facilitates seamless updates and customizations, enabling companies to adapt quickly to shifting manufacturing needs and technological improvements without having incurring considerable cash expenditure. Additionally, Easson's unwavering dedication to consumer-helpful computer software interfaces and comprehensive coaching applications makes certain a seamless integration course of action and optimal utilization of their Highly developed technologies, empowering operators to maximize the equipment’s potential.

In summary, vision measurement engineering click here signifies way over just a classy top quality Manage tool; It's a strategic critical for suppliers in search of to potential-proof their operations and keep a competitive edge in the present demanding industry. By embracing the strength of AI integration, serious-time information Investigation, and hugely scalable solutions like Easson's Highly developed three-axis CMM equipment, makers can obtain unparalleled levels of precision, greatly lower downtime, optimize manufacturing performance, and eventually travel important enhancements in profitability. The strategic expense During this transformative know-how isn't basically an option but a requirement for extended-term success. Take the proactive step to explore how State-of-the-art vision measurement alternatives can empower your online business to thrive within the ever-evolving production landscape, and achieve out to your trusted eyesight measurement machine provider to debate your certain requirements and needs these days.

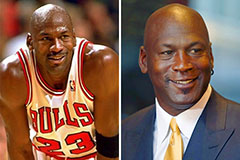

Michael Jordan Then & Now!

Michael Jordan Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!